When choosing a stone crusher, the important thing is that you find the right crushers the first time. This not only saves you time but also saves you money in the long run. The first thing you need to know is which machine best suits your material.

Geology is very important in this case. You need to know what material you want to work with, be it sandstone, limestone, or granite. Since the characteristics of each raw material are very different,

you must determine whether you need a compression crusher or an impact crusher.

Knowing the material you are going to crush will help you choose the right type of stone crusher. Which you will need. You need to know how difficult it is to crush the material, as well as how abrasive it can be. Some materials contain high amounts of silica, such as sandstone,

which is a more abrasive material that wears out your liners faster. Compared to something that might not be very abrasive like limestone.

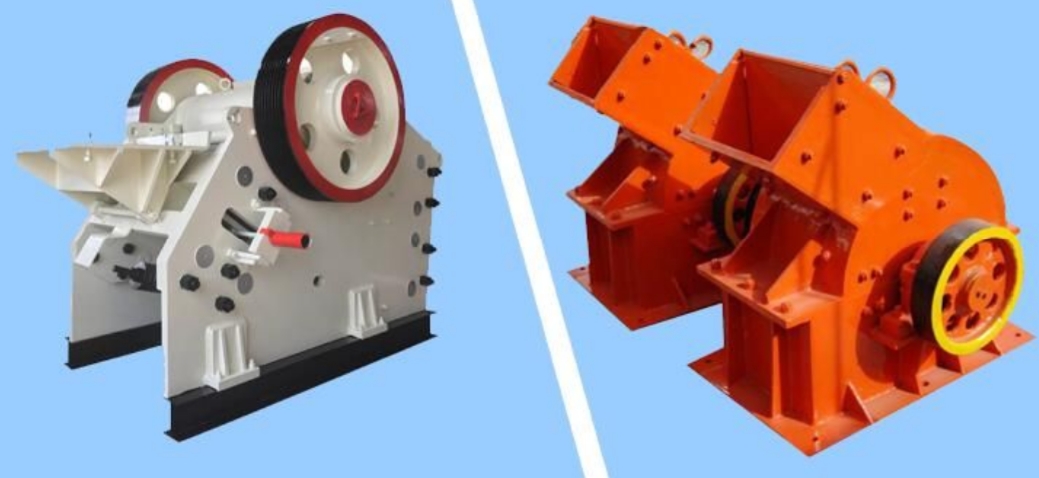

Compression crusher or impact crusher?

Once you understand the material you will be crushing, you need to decide which type of crusher is right for you. Compression-type crushers such as jaw crushers or cone crushers are usually used with many abrasive materials. Impact crushers such as horizontal shaft impactors or vertical shaft impactors are more used for less abrasive material.

Some plants will use both crushers. For example, the result can also determine what type of crusher you need. If stone shape is an issue, an impact crusher will give you a

slightly better shape and give you more cubicity in the final product. Many times, customers will have existing plants that have crushers that produce a significant amount of flat and elongated parts. They might have something like an abrasive stone,

but they might put an impact-type crusher in the line to help shape the material.

New generation cone crushers have made significant changes to the stroke and speed

of the machines resulting in a more cubic product. Cubicity can be better controlled with these types of machines, if you don’t

exceed what we call the reduction factor, which is how far we crush the stone in one step.

Protect your crushers

There are many types of safety devices on these machines that help protect it from damage. For example, a jaw crusher has a switch plate that is a fuse. If you get into this chamber and don’t crush it, the switch

plate will bend or break before you do any serious damage to the bearings or shafts. Cone crushers are equipped with tramp unloading systems that allow crush-free passage without damaging the machine.

Don’t decide before you know all the facts

Sometimes people have preferences based on the type of machine they have always used. They may have misconceptions about new generation crushers, for example, they may result in too many fines.

This is something that can be fixed by adjusting the speed or the way the circuit is tuned. This allows people to have new technology and a machine that is superior to what they are used to. Also, remember that every quarry is different, so just because one company does something one way doesn’t mean you can automatically do the same.